ChiroBlock's ReDesignFactory

ChiroBlock's ReDesignFactory Chemical Process Development & Route Scouting, Route (Re)Design, and Optimization Service

ChiroBlock's long and successful track record in contract research on chemical syntheses and the service of customized, new, and complex molecule synthesis lay the groundwork for our ability to scout for new/better/ alternate routes to your molecules.

Whether you are seeking a patent-free approach to your molecules or a synthetic route optimized in terms of time, amount of by-products, environmental impact, yield, purification, or other parameters – ChiroBlock's ReDesignFactory is the appropriate service to address these issues. ChiroBlock offers a free initial feasibility check regarding the potential of route optimization.

More importantly, we have an unbiased view of your project, considering all synthesis technologies and not just the most sophisticated ones. We start by assisting you to "ask the right questions". Many projects fail because customers not completely familiar with all aspects of chemical syntheses ask for a technology instead for a solution, or approach a technology provider/manufacturer instead of discussing the problem with an independent advocate of their interests – someone who knows the in- and outside of all synthesis options including their individual advantages and drawbacks.

At ChiroBlock, every chemical process development project starts with such consulting and a feasibility check – at no cost to the customer.

Why a newly developed process can save time/ costs and reduces risks. Why an optimization/re-design of your synthetic routes is definitely worth a try:

Nowadays, the rapid development of new approaches, compounds, and molecules, as well as the increasing number of new technologies being available make it difficult to keep pace with the progress in each and every field. Today’s methods and approaches are quickly a matter of yesterday, implying that it can be hard to estimate which development is worth to be considered and which is not.

Moreover, the availability of new synthesis technologies, starting materials, safety regulations, IP restrictions, and equipment are quite hard to monitor. ChiroBlock assists customers to decide on an appropriate technology.

Furthermore, if it comes to very special problems we cannot tackle on our own, we gladly make use of our close connections with various specialized technology providers. With our 100% dedication to contract synthesis and chemical synthesis R&D, it is an essential part of our every day work to develop innovative and sustainable approaches to molecules exhibiting special properties.

Our long-term experience in R&D on chemical synthesis and the custom synthesis of new and complex molecules lays the groundwork for our ability to scout for new, better routes to known molecules. This "ability" is not just an idea or opinion, but is rather backed by unique tools for combining internal and external know-how and by special approaches of managing chemical risks, projects, and quality, which allows us to offer a first feasibility check for free.

To sum it up:

- an optimal lab-scale development of a synthesis route determines the subsequent manufacturing costs and the competitive edge

- a newly designed process/route optimized towards your special requirements will promote cost- and time-effectiveness

- ChiroBlock will help you to increase the efficiency of your processes based on an unbiased and optimal selection of the latest technologies and provide you with a re-designed synthesis exploiting the advantages of our specialization on synthetic R&D

If you are interested in our innovative “ReDesignFactory” process and want to know how we sketch and optimize synthetic approaches applying our “R&D Synthesis Platform”, please do not hesitate to contact us.

How process development at ChiroBlock generates innovative approaches to increase the efficiency of your chemical processes & synthetic routes:

Similarly to two complementary business lines, “MoleculeFactory” and “IP-Factory”, the “ReDesignFactory” is also based on ChiroBlock’s “Synthesis R&D-Platform” comprising proprietary tools for managing processes, knowledge, quality, and risks.

Consequently, we are able to offer most of our services – even risky tasks – on a “fee for results” basis. With more than 5,000 different reactions per year and a track record of about 20 years, our synthetic chemists have the experience and know-how to solve demanding synthesis problems in an economical way.

We are bridging the gap between basic research at public institutes on the one hand and the manufacturing industry on the other hand, having the knowledge of both worlds and speaking both languages. As a consequence, we offer solutions that are both innovative AND aligned with industrial requirements.

Many such solutions have been sold to customers who wanted to tap a powerful chemical R&D department without investing in own resources or to (regularly) double-check their own findings. We do not claim to be experts in each and every synthesis, purification, and analytic technology.

However, we ARE experts in selecting the most suitable technology for a defined problem, e.g., sometimes an enzyme may be superior to a low-molecular homogeneous catalyst, whereas some conversions may require and justify a flow reactor.

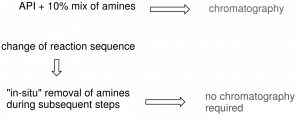

Moreover, there are cases where computational chemistry adds value to a project and others where such an approach would be a waste of resources. There are separation problems justifying the use of counter-current chromatography, whereas other mixtures may require a gel chromatography step.

However, ChiroBlock will find the right solution tailored to your individual needs. Importantly, we do not just suggest such a solution but are able to test it experimentally and, if desired, turn the experimental results into an applicable and validated process.

But why should you outsource these tasks to a specialized chemical service provider like ChiroBlock? Why not address a chemical manufacturer specializing in the technical side of process development?

It goes without saying: Both the selection of a synthesis route toward a target compound and its adoption for large-scale manufacturing are the key factors for achieving efficiency, environmental impact, and competitive edge.

All chemical manufacturers pay much attention to “process development” issues, i.e., the optimization of up-scaling and large-scale manufacturing processes. Normally, dozens of skilled process chemists and engineers are available for carrying out these demanding tasks at each and every chemical producer.

Addressing scale effects and regulatory issues, handling waste management and quality problems, managing capacity utilization and the availability of bulk amounts of starting materials – all these topics are essential to every company engaged in chemical production. The corresponding service providers are as diverse as these tasks are, offering assistance in fine-tuning existing manufacturing processes.

ChiroBlock, however, does not contribute anything to this market. With our focus on applied R&D on chemical synthesis and with more than 50% of our staff being PhD scientists, we do not have the expertise to support large-scale manufacturers in solving these more technological problems. Vice versa, it certainly is not the best idea to approach such manufacturers for developing a very first, an entirely new, or a thoroughly changed synthetic route based on the latest know-how of basic research.

What about the actual route scouting/selection and lab-scale development?

Most chemical manufacturers quite naturally also have resources addressing routing and lab-scale process development, with the validated small-scale procedure being the basis for all subsequent up-scaling and manufacturing steps. However, in most cases, these resources are comparatively weak and sub-optimal for a number of reasons:

- de-novo route development, route scouting, initial lab-scale research and development are risky and expensive

- the required staff and infrastructure differ substantially from those required for manufacturing

- the development of a technologically unbiased approach needs many different experts who cannot be kept busy by only one (internal) client

- such internal lab-scale R&D departments are rarely profitable on their own

- two “worlds” of chemistry have to be merged within such R&D departments: on the one hand, the efficiency and the economical and regulatory aspects of industry and on the other hand, the innovative, creative side of basic research at public institutions in order to quickly transfer the latest research results to an industrial application

- as a consequence, one hardly finds more than a dozen R&D chemists dedicated to routing and lab-scale development even at larger chemical manufacturers.

More often than not, these few researchers have to carry out additional tasks supporting production, trouble-shooting, or analytics. Being an integral department of the manufacturer, these chemists furthermore have been developed in the general ''atmosphere'' of their company, dealing with a more or less homogeneous product and synthesis spectrum. The above aspects leave a gap for a chemical R&D service provider:

- bridging the academic and industrial worlds

- approaching every problem without any technological bias

- taking most of the risks of R&D projects

- offering validated, verified, and reproducible lab protocols ready for subsequent up-scaling and/or production

- possessing purpose-fit equipment und scientific staff

- lacking own large-scale manufacturing facilities and hence not being exposed to the danger of misusing IP sold to customers

- capable of proving the viability of the new route by manufacturing the compound on a "semi-bulk" scale (the first kg as "proof-of-concept") and hence providing the missing link to the real manufacturing process

ChiroBlock offers exactly this service with its “ReDesignFactory”, which is based on a clearly structured, transparent approach to either the optimization of existing syntheses or to the development of entirely new processes.

Customers from various industries can outsource (parts of) their routing and small-scale development tasks to our experts. Regardless of whether you are looking for a patent-free or environmentally more benign way toward a desired compound or just wish to check the availability of new/better catalysts for your key steps, ChiroBlock provides cost-efficient and profound solutions beyond the abilities of most competitors lacking our determined focus.

Examples for chemical process development/ synthesis route optimization projects at ChiroBlock

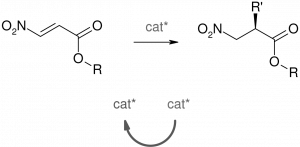

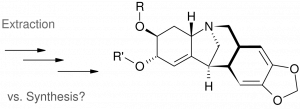

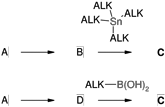

► Due to the constant regulatory pressure to replace tin organyls by less hazardous reagents, one of our customer asked us to develop a "Sn-free" synthesis protocol.

We found a solution to this problem by replacing tin species with a boronic acid, which is not a new invention. However, the challenge was to show that this alternative costs less and provides the target compound of the desired quality, which we achieved by using different intermediates and a new very efficient catalyst.

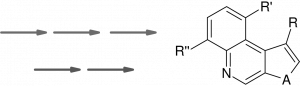

► A consumer product company was looking for a second supplier of a sophisticated high-value low-volume (10 kg p.a.) compound with a set target price. The challenge: Using the established route resulted in costs exceeding the target price.

Nevertheless, we agreed to deliver a first 5-kg batch due to seeing substantial optimization potential. The client was not willing to invest anything into route optimization, requiring only the final compound to be delivered. So, we applied our "ReDesignFactory" to this project at our own expenses to achieve a more than convincing result, i.e., savings of about 30% plus the avoidance of toxic DMF.

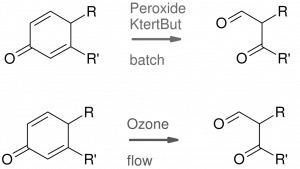

► One customer was interested in improving a Rubottom oxidation–related synthesis step, since the use of peroxides in a batch process posed substantial safety risks and prevented the manufacturing of larger amounts.

We were able to replace the peroxide by ozone and develop a continuous process based thereon. The safety concerns were properly addressed and the new approach was suitable for large-scale production.

show more examples for process developments